High-performance liquid chromatography (HPLC) is a cornerstone technique in analytical chemistry. From pharmaceuticals to environmental testing, it’s relied upon for accurate, high-resolution separations. Yet, one of the most overlooked components in this complex process is the HPLC vial.

A simple container? Hardly. The quality, material, and compatibility of HPLC vials can dramatically impact analytical results. This guide explores everything you need to know - from vial types and septa to future innovations in vial technology.

Introduction to HPLC Vials

What Are HPLC Vials?

HPLC vials are small containers designed to hold liquid samples for injection into chromatographic systems. Typically made from glass or high-grade polymer, they protect samples from contamination while maintaining chemical stability.

Each vial plays a crucial role in ensuring the integrity of the sample, influencing both peak shape and reproducibility in chromatographic results.

Why Vial Quality Matters in HPLC Analysis

Poor-quality vials can lead to sample degradation, leaks, or even ghost peaks - false signals caused by impurities or carryover. For precise results, every detail counts: the vial’s material, cap seal, and cleanliness must all meet analytical standards.

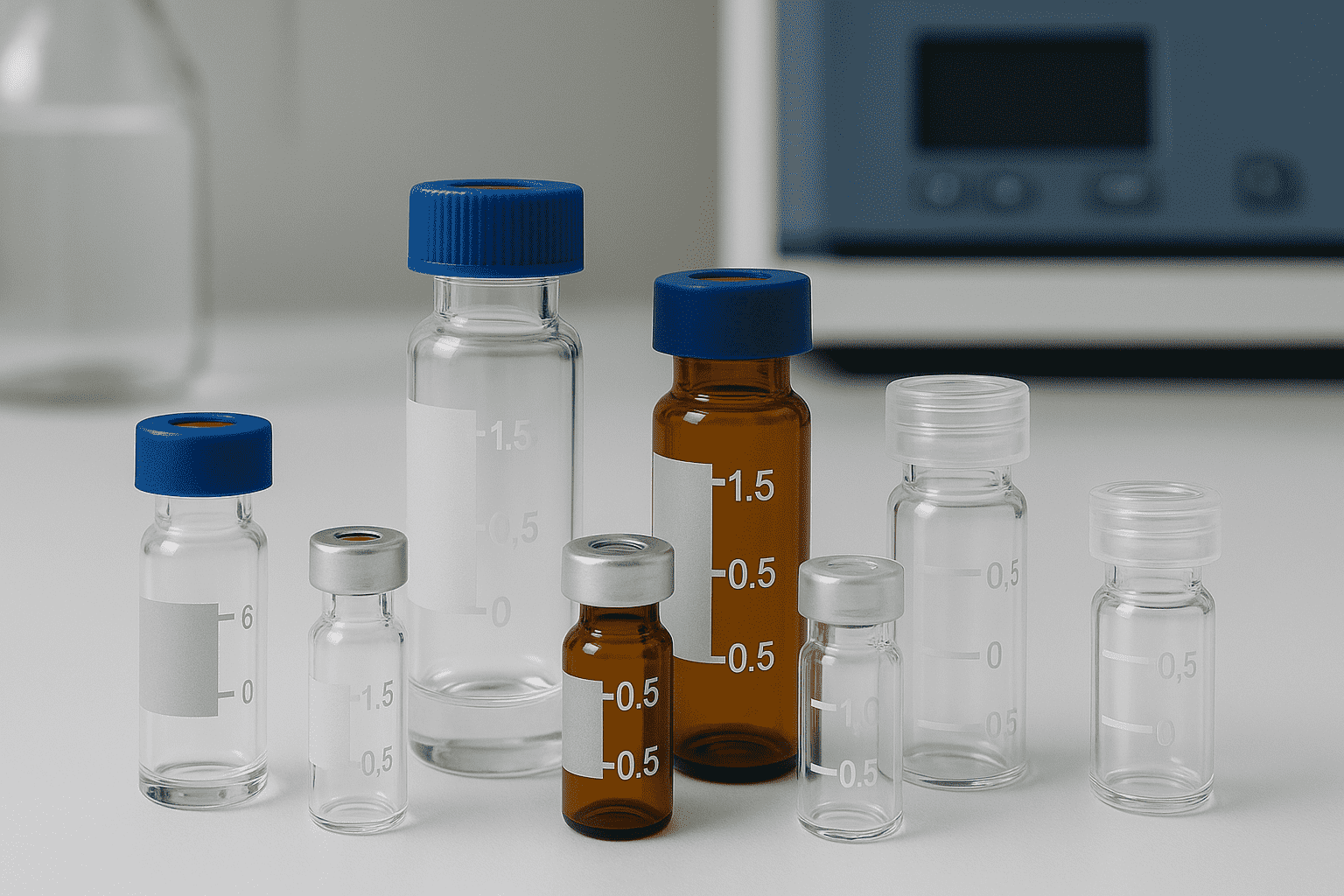

Types of HPLC Vials

Glass vs. Plastic HPLC Vials

Glass remains the gold standard for HPLC vials due to its inertness and chemical resistance. However, plastic vials - usually made of polypropylene - are lightweight, shatterproof, and ideal for aqueous or less aggressive solvents.

-

Glass vials: Ideal for most organic solvents.

-

Plastic vials: Great for aqueous samples and fieldwork.

Screw-Top, Crimp-Top, and Snap-Cap Vials

Each closure style offers unique advantages:

-

Screw-Top Vials: Easy to use, compatible with autosamplers.

-

Crimp-Top Vials: Provide the tightest seal; best for volatile samples.

-

Snap-Cap Vials: Convenient for manual sampling and quick analyses.

Autosampler-Compatible Vials

Modern HPLC systems often rely on autosamplers, which require vials with uniform dimensions and flat bottoms. Some vials even feature barcodes or magnetic caps for automated identification and tracking.

HPLC Vial Sizes and Specifications

Vial Dimensions and Volume Capacities

| Vial Type | Volume (mL) | Height (mm) | Diameter (mm) |

|---|---|---|---|

| Standard Screw-Top | 2.0 | 32 | 12 |

| Wide-Mouth Vial | 4.0 | 45 | 15 |

| Micro Vial | 1.0 | 30 | 8 |

| Headspace Vial | 20.0 | 75 | 22 |

Neck Styles and Thread Compatibility

Different neck designs - such as 8-425 or 9-425 threads - ensure compatibility with specific caps. Choosing mismatched components can lead to leaks or pressure instability.

Septa and Caps: The Unsung Heroes of HPLC Vials

PTFE/Silicone vs. Rubber Septa

Septa create a secure seal that prevents sample evaporation.

-

PTFE/Silicone: Ideal for most solvents, reusable, chemically resistant.

-

Rubber: Cost-effective but not recommended for aggressive solvents.

Cap Materials and Liner Options

Caps are typically made of plastic or aluminum, with optional magnetic or pre-slit liners for autosampler needles. The liner material is often as critical as the septum itself for maintaining sample purity.

Choosing the Right HPLC Vial for Your Application

Chemical Compatibility

Not all solvents interact well with all vial materials. Always check solvent compatibility charts from manufacturers like Agilent Technologies or Thermo Fisher Scientific before purchasing.

Vial Cleanliness and Certification

Pre-cleaned or certified vials undergo rigorous quality control to ensure low extractable levels - crucial for trace analysis.

Common Problems with HPLC Vials and How to Avoid Them

Common issues include:

-

Leaks due to improper cap tightening.

-

Ghost peaks from contaminated vials.

-

Carryover from reused septa.

➡️ Tip: Always use fresh septa for each injection and inspect vials under light for residues.

Maintenance and Storage of HPLC Vials

Store vials in dust-free containers, away from UV light and moisture. Avoid stacking or over-tightening caps, as it can deform the septa.

Simson Chemtech – Leading Manufacturer and Exporter of HPLC Vials

Simson Chemtech is a trusted manufacturer, supplier, and exporter of HPLC vials in India, renowned for its precision-engineered borosilicate glass vials that ensure accuracy, durability, and reliability in chromatography.

With ISO-certified quality standards and a strong global export network, Simson Chemtech serves pharmaceutical companies, research institutions, and industrial laboratories worldwide. Their vials are designed for high chemical resistance, thermal stability, and compatibility with major HPLC systems - delivering consistent, high-performance analytical results.

Cost vs. Quality: Finding the Balance

While low-cost vials might seem appealing, the risk of contamination or analytical drift can cost far more in reruns. Invest in certified vials for critical analyses.

Future Trends in HPLC Vial Technology

By 2025, innovations such as eco-friendly biodegradable plastics, smart caps, and AI-based vial tracking are reshaping laboratories. Expect enhanced traceability and sustainability in upcoming vial lines.

FAQs About HPLC Vials

1.Can I reuse HPLC vials?

Reuse is possible but not recommended for high-precision work.

2.What is the best vial type for volatile solvents?

Crimp-top glass vials with PTFE/silicone septa.

3.Do autosampler vials differ from regular vials?

Yes, they feature consistent dimensions and compatible caps.

4.What size are standard HPLC vials?

Most are 2mL, though sizes range from 1–20mL.

5.Why do I see ghost peaks?

Likely contamination or poor vial cleaning.

6.How should I store empty HPLC vials?

In clean, dry containers, away from direct sunlight.

Conclusion: The Importance of Choosing the Right HPLC Vial

Every chromatographic result begins with a sample - and every sample begins with a vial. Selecting the right HPLC vial ensures analytical precision, reproducibility, and sample safety. As technology evolves, so does the humble vial, bridging the gap between science and sustainability.